<>

In today’s rapidly evolving industrial landscape, Industry 4.0 stands at the forefront, where smart technology, interconnectivity, and real-time data drive operational excellence. Mitsubishi Electric, a key player in automation technology, offers a comprehensive suite of solutions designed to empower manufacturers to leverage these advancements. This article explores how Mitsubishi Electric automation equipment can revolutionize your operations, allowing you to optimize data use, enhance factory efficiency, and significantly uplift productivity. We will delve into impressive cost reductions, strategies for efficient factory management, remarkable productivity improvements, industry recognition, and the realm of intelligent manufacturing.

How are you using your data?

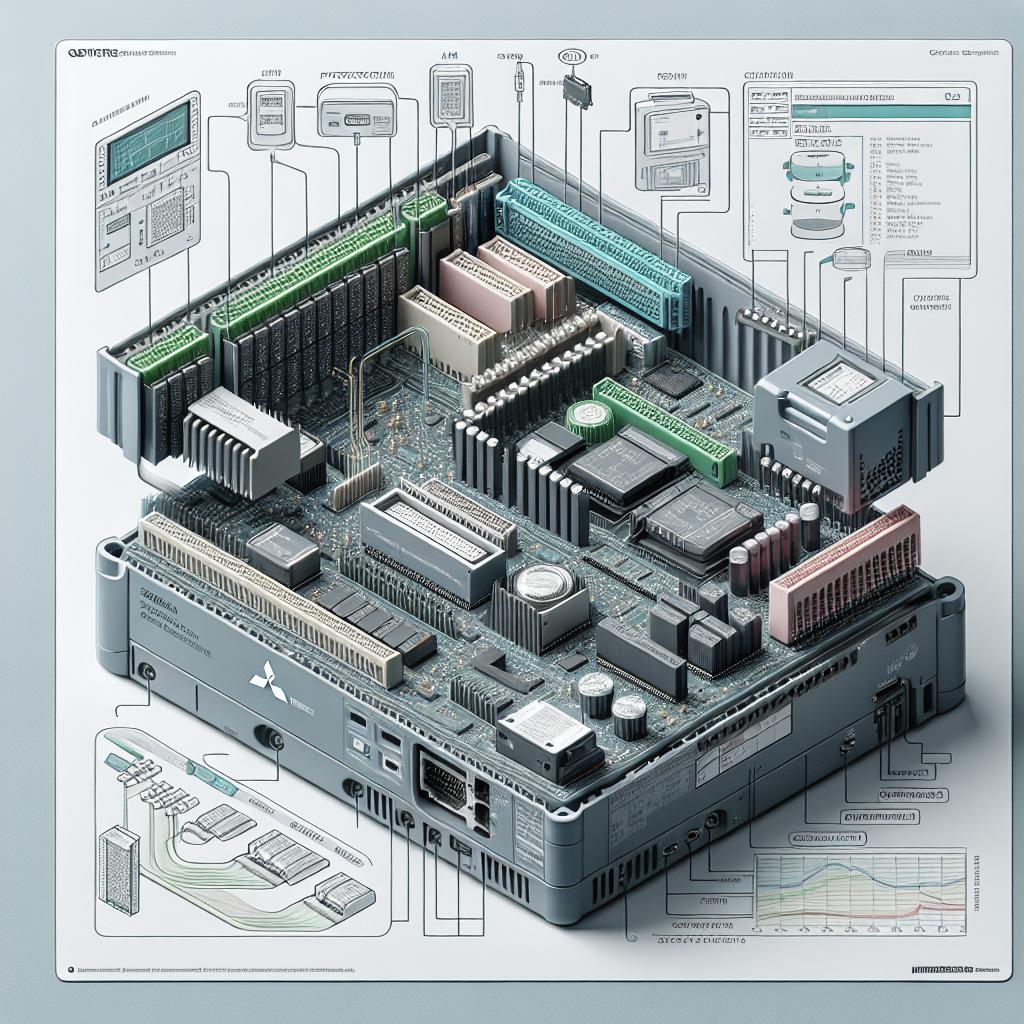

Data is the backbone of modern manufacturing. Mitsubishi Electric understands this and offers cutting-edge solutions to ensure your data is optimized for actionable insights. Their iQ-R series of controllers provides high-speed data processing and real-time data analytics, enabling manufacturers to make informed decisions that boost productivity and efficiency. With technology like the Edge Computing Solution, data processing happens closer to the source, reducing latency and allowing near-instantaneous data analysis. This local data processing capability ensures that critical manufacturing processes are continuously monitored and adjusted in real-time, minimizing downtime and maximizing throughput.

Where are you using your data?

Data utilization isn’t confined to the factory floor. Mitsubishi Electric’s e-F@ctory concept integrates the entire manufacturing ecosystem—from the initial design phase to post-production analytics. By harnessing the power of the IoT and AI, e-F@ctory connects machines, systems, and employees, ensuring data flows seamlessly across all levels of your operation. Whether it’s preventive maintenance, quality assurance, or resource allocation, Mitsubishi Electric’s automation solutions ensure data is used precisely where it’s needed most. The integration with cloud platforms provides a broader data analytics spectrum, helping manufacturers predict trends and make strategic decisions that align with market demands.

You can plan, from start to finish, your own journey to digital manufacturing.

Digital transformation in manufacturing can be an overwhelming prospect. Mitsubishi Electric offers a structured approach, providing tailored solutions that guide companies from traditional methods to cutting-edge digital manufacturing. Their consultative process begins with a thorough assessment of current systems, followed by a customized roadmap to digitalization. Their Total Factory Automation (TFA) solutions cover every aspect of manufacturing—from supply chain management to production control. These integrated solutions allow for a seamless transition to a smart factory, eliminating bottlenecks and streamlining processes across the board.

30% Cost Reduction

One of the standout benefits of Mitsubishi Electric’s automation equipment is robust cost reduction. By deploying energy-efficient machinery and streamlined processes, manufacturers can achieve up to a 30% reduction in operational costs. Technologies like the EcoMonitor leverage real-time data to optimize energy usage, ensure equipment operates within predefined parameters, and identify wasteful practices. Additionally, predictive maintenance solutions minimize the cost associated with unexpected equipment failures. By using advanced sensors and analytics, Mitsubishi Electric enables you to anticipate maintenance needs, thereby reducing downtime and prolonging the lifespan of your machinery.

Efficient Factory Management

Efficient factory management is imperative for staying competitive in the Industry 4.0 era. Mitsubishi Electric’s manufacturing execution systems (MES) provide an encompassing view of operations, allowing managers to monitor production in real-time. These systems offer insights into key performance indicators (KPIs), production bottlenecks, and areas requiring improvement. Their SCADA (Supervisory Control and Data Acquisition) systems further enhance operational efficiency by providing real-time monitoring and control over various factory processes. These systems help in maintaining consistent quality, improving resource allocation, and ensuring compliance with industry standards.

70% Productivity Improvement

Mitsubishi Electric’s automation solutions are engineered to significantly enhance productivity. With automation technologies such as advanced robotics and intelligent control systems, manufacturers can witness up to a 70% improvement in productivity. Robots like the MELFA series are designed to work collaboratively with human operators, enhancing speed, precision, and safety. Their high-performance PLCs (Programmable Logic Controllers) and HMIs (Human Machine Interfaces) ensure seamless operation of complex manufacturing processes. These tools allow for quick adjustments and fine-tuning, enabling factories to adapt rapidly to changing production demands and market conditions.

Winning Awards

Mitsubishi Electric is not just a leader in technology but also a recipient of numerous industry awards, underscoring the effectiveness and innovation of their automation solutions. Recognitions such as the “Best Factory Award” and accolades from industry bodies provide a testament to their commitment to excellence. These awards highlight the company’s consistent pursuit of innovation, reliability, and customer satisfaction. By adopting Mitsubishi Electric’s award-winning solutions, manufacturers align themselves with industry best practices and standards, ensuring they stay ahead of the curve.

Intelligent Manufacturing

At the heart of Industry 4.0 lies the concept of intelligent manufacturing. Mitsubishi Electric’s comprehensive suite of AI-driven solutions, under its AI technology brand “Maisart” (Mitsubishi Electric’s AI creates the State-of-the-ART in technology), enables manufacturers to achieve unprecedented levels of autonomy and intelligence in their operations. From automated quality inspections using advanced vision systems to self-optimizing production lines, Mitsubishi Electric’s intelligent manufacturing solutions ensure that factories are not only smart but also agile and responsive. These innovations drive continuous improvement, making your manufacturing process more adaptable and future-proof.

Future prospects

| Key Area | Summary |

|---|---|

| Data Utilization | High-speed, real-time data processing with iQ-R series and Edge Computing Solution |

| Data Integration | Seamless ecosystem connectivity with e-F@ctory, integrating IoT and AI |

| Digital Transformation | Structured approach with Total Factory Automation solutions |

| Cost Reduction | Achieve up to 30% savings with energy-efficient and predictive maintenance technologies |

| Factory Management | Real-time operational control with MES and SCADA systems |

| Productivity Improvement | Boost productivity by up to 70% with advanced robotics and intelligent control systems |

| Industry Awards | Recognition for innovation, reliability, and excellence with awards like the “Best Factory Award” |

| Intelligent Manufacturing | AI-driven solutions for autonomous and agile manufacturing processes |