<>

When it comes to selecting the best frequency inverters for your industrial applications, Mitsubishi Electric offers a range of high-performance options. These inverters are designed to enhance energy efficiency, improve motor control, and optimize operational productivity. In this blog post, we’ll delve into the standout features, benefits, and applications of five top models: the FR-E800, VFD D700, VFD E700, VFD F800, and VFD A800. By the end, you’ll have a clear understanding of which inverter could be the best fit for your needs.

FR-E800

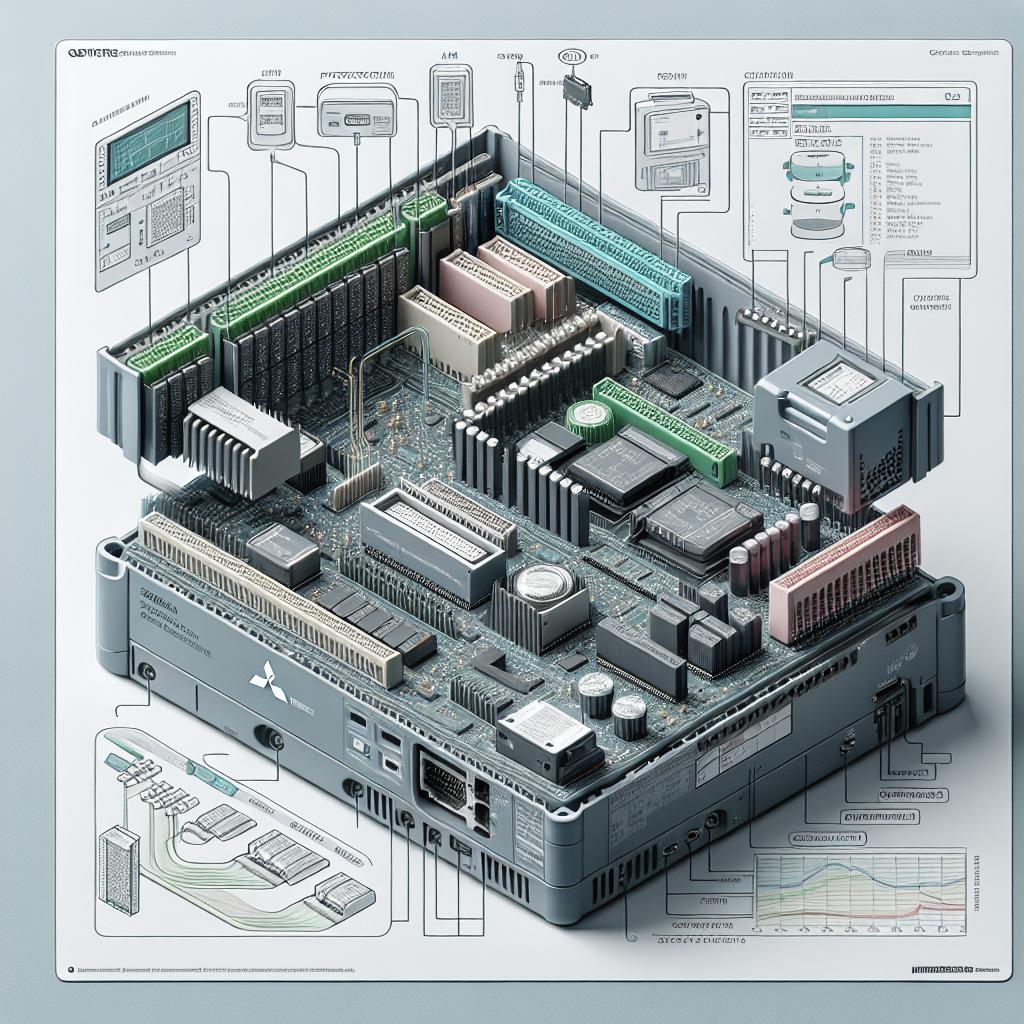

The FR-E800 series from Mitsubishi Electric is equipped with state-of-the-art motor control technology and an array of connectivity options. One of its standout features is the built-in Ethernet and RS-485 communication, which ensures seamless integration into a variety of industrial environments. Moreover, it supports multiple communication protocols such as CC-Link IE TSN, Ethernet/IP, and Modbus TCP/IP, making it versatile and flexible for various automation systems.

Another compelling aspect of the FR-E800 is its predictive maintenance capabilities. By leveraging advanced diagnostics and real-time monitoring, this inverter can help you foresee and preempt potential issues before they become critical problems. This feature significantly reduces unplanned downtime and maintenance costs, thus enhancing overall operational efficiency. Additionally, its compact design is ideal for installations with limited space.

VFD D700

The VFD D700 series is known for its simplicity and ease of use, making it an excellent choice for applications requiring basic motor control. Its user-friendly interface coupled with straightforward parameter settings enables quick installation and setup. This inverter series is especially useful for small to medium-sized applications where cost-effectiveness and reliability are key considerations.

Equipped with a built-in RS-485 communication port, the VFD D700 provides easy integration into existing networks. Despite its straightforward design, it doesn’t skimp on performance. The inverter boasts robust vector control, ensuring smooth and precise motor operation. Overall, the VFD D700 is a reliable workhorse suitable for a range of industrial tasks.

VFD E700

The VFD E700 series combines advanced features with ease of use, providing a balanced solution for various industrial needs. One of its main strengths is its integration capability. With options for built-in USB and RS-485 ports, it offers versatile connectivity options that facilitate easy system integration and data communication.

Another noteworthy feature is its energy-saving capabilities. The VFD E700 employs advanced algorithms designed to optimize power consumption, thereby reducing operational costs. Its ability to support sensorless vector control ensures precise motor control and stable performance under varying loads. This makes it an excellent choice for applications where energy efficiency is a priority.

VFD F800

The VFD F800 series is specifically designed to optimize fan and pump applications. Among its many features, the most impressive may be its advanced PID control functions. These controls ensure that the system operates at the most efficient settings, maximizing energy savings while maintaining optimal performance. This makes the VFD F800 especially valuable in HVAC and water treatment plants.

The inverter also offers advanced harmonic suppression functions, enhancing the quality of the electrical system and reducing harmful harmonics. With multiple communication options and built-in EMC filters, the VFD F800 promises seamless integration and compliance with international standards. Its specialized features are designed to address the unique challenges of HVAC and pump applications, ensuring reliable and efficient operation.

VFD A800

The VFD A800 series is the flagship model, providing unparalleled performance and flexibility. Designed to cater to high-end industrial applications, it offers exceptional motor control capabilities. With a high-speed processor and advanced vector control algorithms, the VFD A800 delivers precise and efficient motor performance even in the most demanding scenarios.

A standout feature of the VFD A800 is its extensive connectivity options, including CC-Link IE Field, Modbus, and Ethernet/IP. This allows for seamless integration with various automation systems, making it highly adaptable. Additionally, its robust design and built-in safety features ensure reliable operation, even in harsh industrial environments. The VFD A800 is the go-to solution for industries requiring top-tier performance and advanced features.

Summary of Main Points

| Model | Key Features | Applications |

|---|---|---|

| FR-E800 | Advanced motor control, Predictive maintenance, Ethernet and RS-485 communication | General industry, Complex automation systems |

| VFD D700 | User-friendly interface, Built-in RS-485, Basic vector control | Small to medium-sized applications |

| VFD E700 | Energy-saving algorithms, Built-in USB and RS-485 ports, Sensorless vector control | Energy-efficient applications, General industry |

| VFD F800 | Advanced PID control, Harmonic suppression, Built-in EMC filters | HVAC, Water treatment plants |

| VFD A800 | High-speed processor, Extensive connectivity, Robust and flexible design | High-end industrial applications |