<>

“`

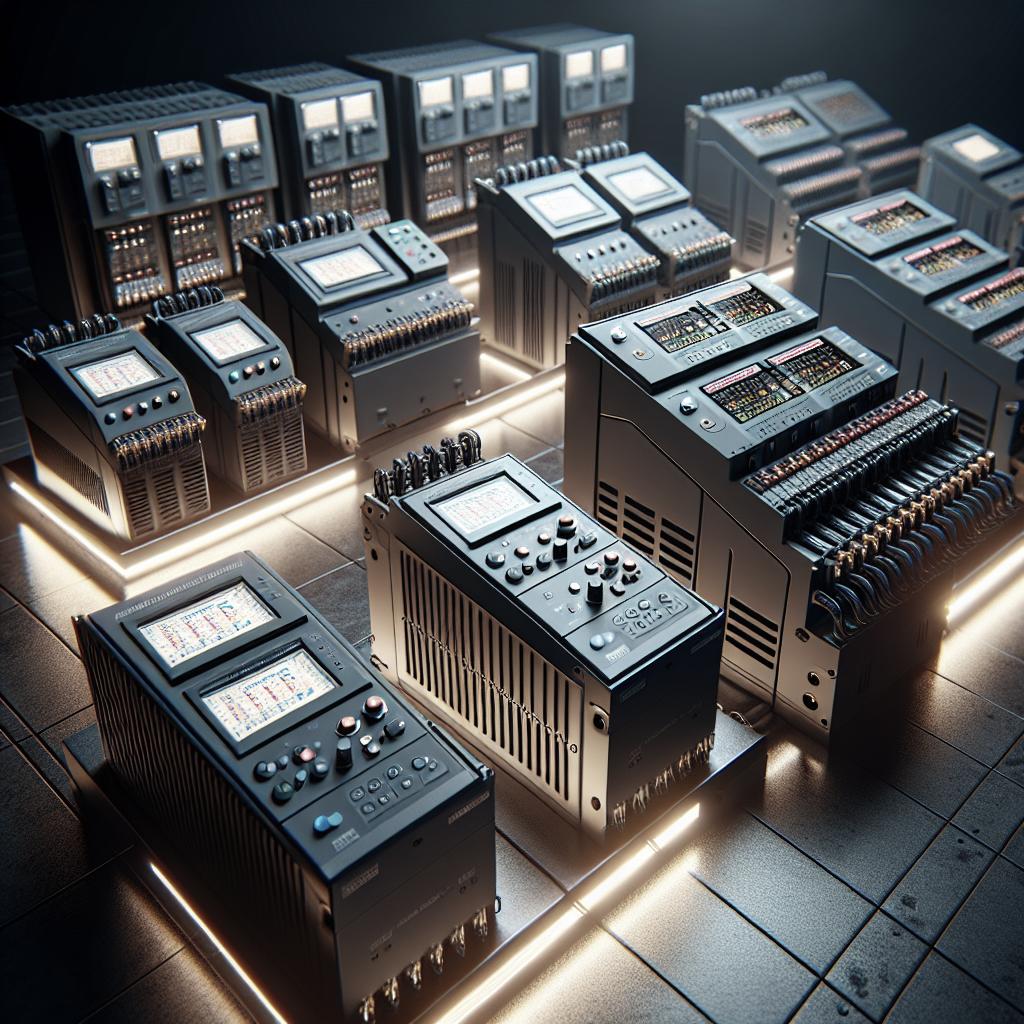

Mitsubishi Electric is a renowned name in the automation industry, offering an extensive range of programmable logic controllers (PLCs) that cater to diverse industries and applications. PLCs serve as the backbone for automated systems, helping control machinery, processes, and various functions with precision and reliability. This blog post delves into the inner workings of five Mitsubishi Electric PLC families: iQ-F, FX Series, iQ-R, iQ, and L Series. Each section provides a detailed understanding of the unique features, components, and functionalities that make these PLCs essential for modern automation solutions.

iQ-F PLC

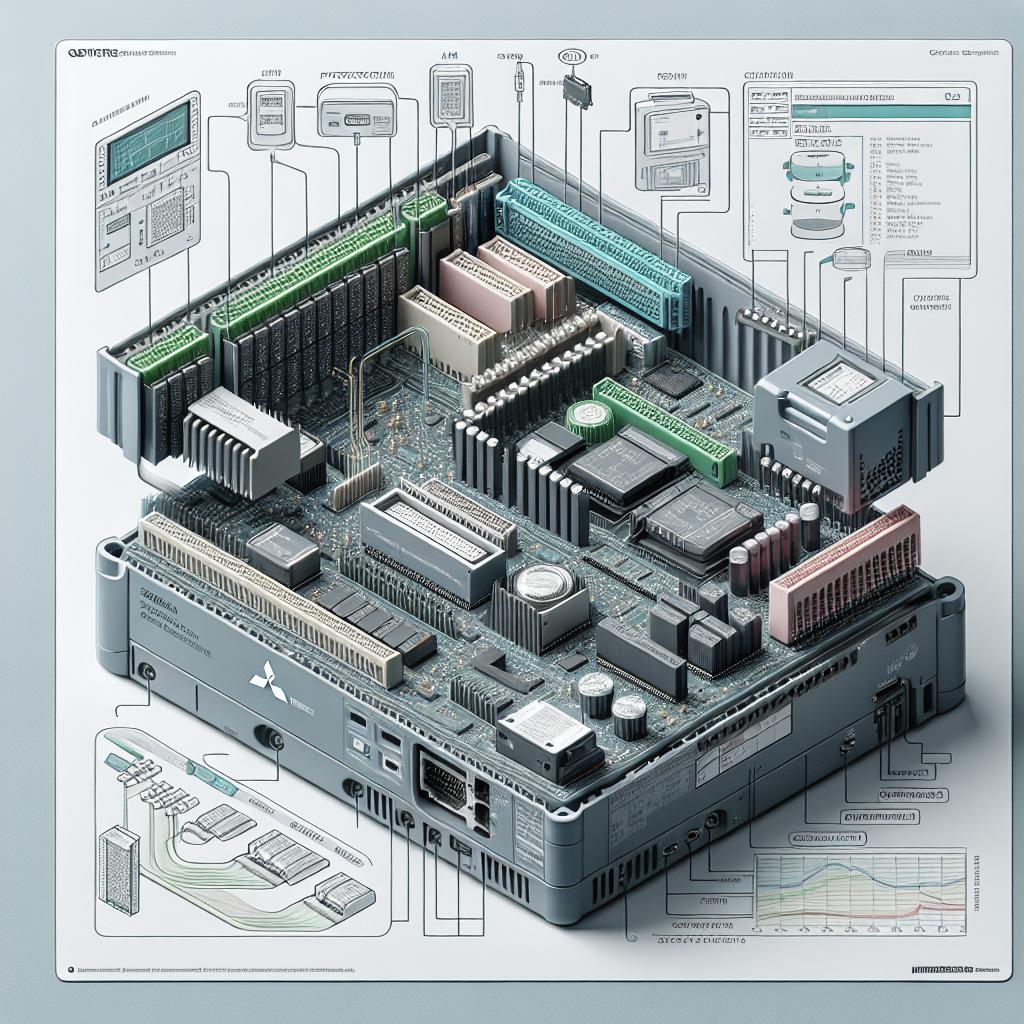

The iQ-F Series from Mitsubishi Electric stands out for its compact design and cost-effectiveness, making it an ideal choice for small to medium-sized applications. This series is engineered for easy installation and maintenance, featuring built-in high-speed processing capabilities that reduce cycle times and enhance productivity. The iQ-F PLCs also support various communication protocols, enabling seamless integration with other devices and systems.

One of the notable features of the iQ-F Series is its comprehensive array of built-in I/O options, which offer flexibility and adaptability to various control needs. The built-in Ethernet port facilitates efficient networking and remote monitoring. Additionally, the iQ-F PLCs provide robust security measures, ensuring that access is restricted to authorized users, thereby safeguarding sensitive data and operations.

FX Series PLC

The FX Series is Mitsubishi Electric’s flagship line of micro-PLCs, known for its versatility and performance. Designed for small to medium automation tasks, the FX Series offers a wide array of functions and is capable of handling complex computations and control processes. One of the principal advantages of the FX Series is its scalability, which allows users to expand the system easily as their application requirements grow.

FX PLCs come equipped with a variety of communication options, including Ethernet, RS-485, and CANopen, ensuring that they can be integrated into a myriad of network environments. These PLCs also feature advanced instruction sets that support various programming languages, making them suitable for applications such as industrial machinery control, building automation, and process management. Furthermore, the FX Series offers robust performance in harsh environments, ensuring reliability and longevity.

iQ-R PLC

The iQ-R Series represents a high-performance and highly reliable family of PLCs designed for complex and large-scale automation systems. Known for its speed and precision, the iQ-R Series is capable of handling heavy data loads and rapid processing tasks. One of the standout features of the iQ-R PLC is its synchronized motion control capability, which allows for precise and coordinated movements in applications such as robotics and advanced manufacturing.

iQ-R PLCs are built on a modular architecture, providing outstanding flexibility and scalability. This modular design enables users to build customized solutions tailored to specific needs, making it highly adaptable across different industries. Security is another key highlight, with the iQ-R Series offering multiple layers of protection against cyber threats and unauthorized access. Additionally, these PLCs feature enhanced diagnostic and maintenance tools that facilitate quick troubleshooting and minimize downtime.

iQ PLC

The iQ Platform is Mitsubishi Electric’s integrated automation solution that harmonizes control, visualization, and information processing into a unified system. The iQ PLCs are central to this platform, designed to optimize performance, efficiency, and connectivity across various automation tasks. The iQ PLCs feature a multi-CPU system architecture, enabling parallel processing and reducing execution times for complex operations.

Another distinctive aspect of iQ PLCs is their extensive compatibility with a variety of modules, including analog, digital, motion control, and communication modules. This compatibility ensures that users can integrate diverse functionalities within a single system. The iQ PLCs also come with comprehensive software tools for programming, monitoring, and diagnosing, facilitating smoother project development and management. These PLCs are particularly advantageous for applications requiring high-speed processing and precise control.

L Series PLC

The L Series PLCs are known for their compact size and powerful features, making them suitable for a wide range of automation tasks. Designed to be user-friendly, the L Series PLCs offer a “one-touch” solution with easy-to-configure interconnectivity options. These PLCs are powered by a high-performance CPU, which ensures rapid processing and reliable operation across various applications.

Customization and expandability are key features of the L Series. Users can easily add I/O modules, communication modules, and special function modules to match their specific requirements. The L Series PLCs also support a range of communication protocols, including CC-Link, Ethernet, and RS-232/485, making them highly adaptable to different network environments. Furthermore, the L Series is designed with energy efficiency in mind, reducing operational costs while maintaining top-tier performance.

Lessons Learned

| PLC Series | Key Features | Applications | Strengths |

|---|---|---|---|

| iQ-F PLC | Compact design, built-in I/O, Ethernet connectivity, robust security | Small to medium-sized applications | Easy installation, cost-effective, flexible |

| FX Series PLC | Versatile functions, scalable, multiple communication options | Industrial machinery control, building automation, process management | Performance in harsh environments, advanced instruction sets |

| iQ-R PLC | High-speed processing, synchronized motion control, modular architecture | Complex, large-scale automation systems | Flexibility, scalability, enhanced security |

| iQ PLC | Multi-CPU architecture, broad module compatibility, comprehensive software tools | High-speed, precise control applications | Optimized performance, extensive connectivity |

| L Series PLC | Compact, high-performance CPU, customizable, energy-efficient | Wide range of automation tasks | User-friendly, flexible interconnectivity |

“`